Early Engines |

| Cameron .09 - .045 Special - Space Bug Jr. - Space Bug - Thermal Hopper - Strato Bug - Space Hopper - Olympic - Sportsman |

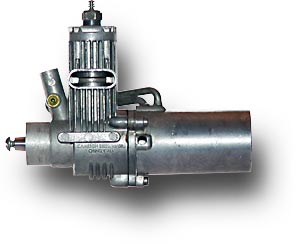

Cameron .09 (1.5 cm³)

Manufactured in 1949

Well, this is not really a Cox engine, but closely connected to Cox history. The basic engine is probably from a Cameron "Rodzy" car, because of the straight cut exhaust. I am not sure - the fuel tank seems to be from a Cox Champion car, and the mounting lugs are undrilled. Maybe one of the readers can tell me more?

The cylinder is of unusual oval shape with vertical cooling fins. The fuel tank is equipped with two rigid filler tubes and a plastic tube is required to connect the fuel feed hole at the side to the carburetor. Therefore the engine must be mounted so that this hole points to the outside of the tether circle, usually with the crankshaft pointing towards the rear.

Cox bought these engines from the Cameron Brothers which were first located in Chino, later in Sonora, California.

Manufactured in 1949

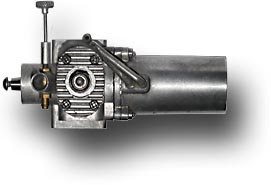

This engine was the first engine which was designed and at least partially manufactured by Cox.. Only a few but vital parts like piston and cylinder were purchased from Mel Anderson. The engine was used in the Cox Special tether car, which was a big success in the market.

The design is very clever and resulted in a relatively cheap power unit named "Power Pak" which could be easily added to race cars.

The parts breakdown shows the core engine at the bottom center. The planetary gearbox at the left has three small gears and is lubricated by the oil in the engine exhaust. The exhaust gas passes through the rectangular exhaust pipe at the upper left. To the right of the engine block we see the fuel tank unit with a large wire screen filter and the hollow axle. Twin reed valves are used and a standard glow plug. This reed valve system can be found later in the Space Bug engine.

This engine already shows a remarkable complexity and high precision which was later to become typical for Cox.

{upper picture lifted from eBay}

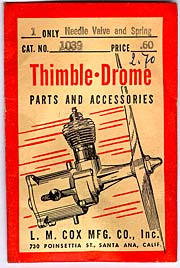

Space Bug .049 (0.8 cm³)

Manufactured in 1952 (#349)

This was the first engine design completely developed by Leroy Cox and his partner Mark Mier. It hit the market in 1950 and came with a shiny, cast aluminum tank. According to the internal fuel system, it seems to have been intended for use in C/L models (R/C with these small engines was not yet possible in these years, as R/C sets were bulky and heavy). The early engines came in a blue cardboard box, which was replaced in later years by the bubble box, like the one shown below for the Thermal Hopper. Later models also used the new glow head with the copper gasket at the bottom of the thread. Note the ordinary glow plug on the parts bag - as far as I have heard, the glow head replaced this option only a few months after the Space Bug was introduced. On the other hand it may never have been produced with the ordinary glow plug - the paper bags had to be produced in advance and might show an artists impression of a prototype engine.

Of course, the fuel tank was designed for control line flight — pickup tube and needle valve were directed towards the outside of the flying circle (the sectional cut shows a top view with angled fuel passage, needle thread with orifice and the center venturi channel).

Manufactured in 1953 (#370)

While the standard Space Bug had a large aluminum tank, the Junior came with a smaller plastic fuel tank.

Like the early Space Bug above, these two engines still have the glow head with the smaller thread diameter. They also have the original three piece piston with an aluminum conrod. The reed valve system consisted of two reeds in tandem, one having a thickness of approximately 0.05 mm (1/500") and the second one being about 0.08 (1/300") mm thick.

As a cost reduction measure the cylinder of the Space Bug Jr. has only one bypass port.

Engines like these were used in the Thimble Drome control line models, for example the first issues of the TD-3. The last version of the TD-3 came with the then brand new Babe Bee engine.

Manufactured circa in 1955 (#370)

These engines already have the new single piece piston and cylinder design, which was used for the next 50 years on all Cox engines. Also the reed valve assembly was simplified and now used only one reed of 0.13 mm (1/200") thickness. Finally, the glow heads have the large thread which became Cox standard for the next 50 years. The remaining parts are identical, except for the colored fuel tanks.

The color was usually chosen to match the firewall of the models equipped with these engines (TD-3, Prop Rod, Water Wizard).

I am still looking for a sample with a black plastic tank.

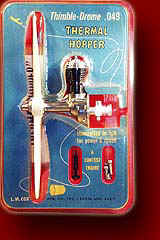

Thermal Hopper .049 (0.8 cm³)

Manufactured in 1955 (#360)

This

early engine uses the cast crankcase of the Space Bug engine and sold for

the same price ($6.96 in 1953). Basically it is a Space Bug without fuel

tank. Instead, a circular backplate for mounting on a firewall was added.

The pretty bubble pack also fits the Space Bug. Like any reed valve engine,

the engine was capable of running in both directions, and the manual

suggests to "stop it by putting finger over propeller nut and putting

pressure on propeller" - well, that's a great idea! I would not really

recommend to try it, except if you like to experience real nostalgia

feelings including cuts and bruises.

This

early engine uses the cast crankcase of the Space Bug engine and sold for

the same price ($6.96 in 1953). Basically it is a Space Bug without fuel

tank. Instead, a circular backplate for mounting on a firewall was added.

The pretty bubble pack also fits the Space Bug. Like any reed valve engine,

the engine was capable of running in both directions, and the manual

suggests to "stop it by putting finger over propeller nut and putting

pressure on propeller" - well, that's a great idea! I would not really

recommend to try it, except if you like to experience real nostalgia

feelings including cuts and bruises.

reprint of instructions in PDF format

reprint of test report in PDF format (Aeromodeller February 1954)

reprint of test report in PDF format (Model Aircraft August 1955)

( manually re-typed facsimile

document with permission of the publishers)

Thermal Hopper .049 (0.8 cm³)

Manufactured in ca. 1960 (#150)

Here we have another Thermal Hopper, mounted on the

so called "Bird Cage" engine mount. Using this delicate piece of aluminum,

the engine could be mounted flat on a firewall without having to provide an

opening for carburetor and needle valve of the standard Thermal Hopper.

An additional accessory, often combined with the bird cage mount, was a twin

needle valve carburetor which allowed for two engine speeds using a timer or

an additional control line.

I am still looking for a sample of the twin needle valve assembly.

Strato Bug .049 (0.8 cm³)

Manufactured in ca. 1954-1956 (#380)

The Strato Bug looks like a mix of a Space Bug and

a Space Bug Jr.

The main features are the new cylindrical metal fuel tank #381 with matching

backplate #382 and the Space Bug cylinder having two bypass ports. So this

is a performance engine at moderate cost ($5.95 compared to $6.95 for a

Space Bug and $3.95 for a Space Bug Jr. in 1953).

For C/L operation, the backplate would have to be turned so that the needle

valve points to the center of the flight circle. The spun tank was the first

step towards the Babe Bee type engine, replacing the expensive casting of

the Space Bug. The cross vented tank system can also be found later again in

all larger Bee tanks.

So far I have seen red and yellow backplates on these engines. These engines

came with the old style glow head, the thin walled, two bypass cylinder and

the two part pistons with aluminum connecting rod.

{picture of yellow backplate engine courtesy Neal Dawson, USA}

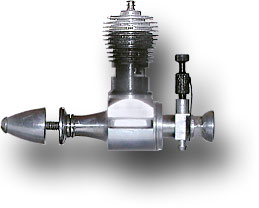

Space Hopper .049 (0.8 cm³)

Manufactured in ca. 1959 (#150?)

This nice engine looks like a small Sportsman and is as powerful as a Tee Dee .049. The engine breathes through a reed valve and the carburetor is located on the rear end. It turned a 6x3" propeller at more than 17'500 RPM. The bubble pack contains screws and a pair of matching mounting brackets. The design was performed by Dale Kirn.

A small run of sample engines was also produced with ball bearings, but performance was not improved. The later Tee-Dee series delivered more power and was more economic to manufacture.

I

am still looking for a sample of the ball bearing version for my museum.

I

am still looking for a sample of the ball bearing version for my museum.

The box of this beautiful sample has a inlay card printed in color, gold and silver. Other cards were printed on a cheaper cardboard without using gold and silver paint. Maybe someone knows more about this?

reprint of instructions in PDF format

{engine has been donated by Peter Soule, USA}

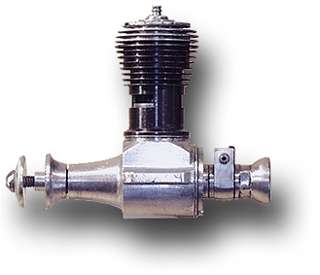

Olympic .15 (2.5 cm³)

Manufactured in 1959-1961 (#140)

This

engine has two ball bearings and the inlet is reed valve controlled. It was

designed by Dale Kirn for use in FAI competition. The engine came in a

plastic bubble box with a red bottom and a nice inlay card. The maximum

power output was about 215 W @ 16'500 1/min using a fuel having 20%

nitromethane content.

This

engine has two ball bearings and the inlet is reed valve controlled. It was

designed by Dale Kirn for use in FAI competition. The engine came in a

plastic bubble box with a red bottom and a nice inlay card. The maximum

power output was about 215 W @ 16'500 1/min using a fuel having 20%

nitromethane content.

instructions in PDF format (including typos of original manual)

test report

in PDF format (Aeromodeller November 1959)

test report in PDF format (Model Aircraft July 1959)

(these are manually re-typed

facsimile documents with permission of the publishers)

{engine has been donated by Peter Soule, USA}

Olympic .15 Drum Valve (2.5 cm³)

Prototyped in 1963(?)

A number of modified Olympic engines, which had been equipped with a drum valve inlet, was given to control line and free flight competitors, but this design did not make it into production. The conversion was probably part of Bill Atwoods design path towards rotary valve engines. At about the same time he started development of the Tee Dee series and the Tee Dee .15 proved to be more powerful and more economical to produce than this Olympic variant.

{Picture courtesy Cole Chevalier , USA}

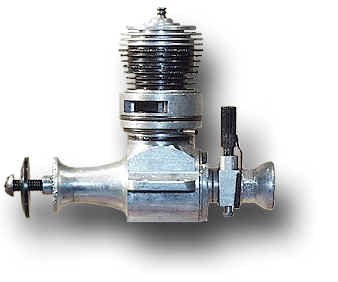

Sportsman .15 (2.5 cm³)

Manufactured in 1958-1965 (#110)

This engine is similar to the Olympic, but has plain bearings, which resulted in a lower price ($7.98 in 1658, to be exact). The aluminum parts were not colorfully anodized as its stronger brother, the Olympic. Again, Dale Kirn was responsible for the design of this engine which followed the Space Hopper and Olympic design philosophy.

The engine was also used as a product engine in the beautiful "Big Comanche" C/L model. This was the only .15 powered ready to fly C/L model Cox ever manufactured. Here, the engine was equipped with a longer needle valve and a spinner.

Sportsman .15 (2.5 cm³)

Manufactured in 1958-1965 (#110)

Here we have another Sportsman, this time with an interesting third party exhaust throttle (Roto-Throttle). The throttle ring can be rotated by an R/C servo.

Over the years, similar exhaust throttles have been produced by many companies - it took Cox astonishingly long until they came out with efficient mufflers and R/C carburetors.