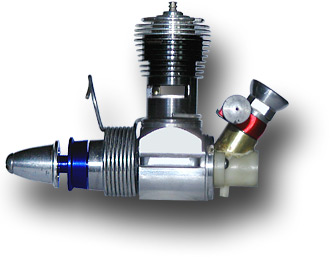

Olympic .15 Rotary |

Sample Type

A

{Picture courtesy Cole Chevalier , USA}

The white plastic rear end of this engine slides over the cylindrical extension of the aluminum crankcase cover. It is held in place by an aluminum cap which screws into the end of the stub. The rotary valve is contained inside the extension. The venturi carburetor is screwed into the thin walled plastic part, similar to the Tee Dee engine design. It also carries a pressure takeoff nipple on the right side. The plastic parts are prone to cracking around the carburetor stub.

Sample Type B

The molded plastic part is attached to the rear end by two small screws. Inside the plastic casing, an aluminum tube provides the bearing surface for the rotary valve and the window for inlet timing. Its rear end is open and only closed by the plastic part. As a repair solution, a brass ring has been glued over the very thin walled carburetor stub. The nipple at bottom could be used for pressure takeoff, but is not drilled.

Threaded holes are drilled into the backplate every 45 degrees, which together with elongated holes in the plastic part allow for a wide adjustment of the inlet timing.

Olympic .15 Rotary (2.5 cm³)

Prototyped in 1966(?)

A prototype of the rear drum valve intake .15 Olympic engine. Based on the Olympic .15, the rear end has been modified. The reed inlet valve of the Olympic has been replaced by a rotary valve (drum valve). The engine was another child of engine designer Bill Atwood, who was hired by Leroy Cox in 1960 to develop a reed valve .010 engine. When the tiny reed valves did not work as expected, Bill started to experiment with rotary induction systems and was keen to bring more powerful Cox engines into the .15 FAI contest class.

The engine is a predecessor of the Tee Dee series, which placed the rotary inlet at the forward end of the engine. Besides being a more conventional design, the number of parts and manufacturing steps required for a Tee Dee is lower (no extra rotary valve, no ball bearings), leading to lower production costs. It is said that the performance of the engine was not up to the expectations, but the lower part count of the Tee Dee design may have been the true reason behind not putting the Olympic into production.

About 50 sample engines of the rotary valve Olympic have been produced and many of these have been given to prominent modelers to test the engines in control line and free flight contests.

Obviously prototypes were made in different variants. My sample (type B) has a quite different rear end compared to the type A variant. It offers more freedom for adjusting timing which would be typical for an experimental engine.

|

dimensions |

|

| bore | 15.0 mm |

| stroke | 14.1 mm |

| swept volume | 2.459 ccm |

| 0.150 c.i. | |

|

timing |

|

| Exhaust port | 131° |

| transfer ports | 116° |

| inlet timing | 190° |

The rear view with screws removed shows the elongated holes to adjust the inlet timing.

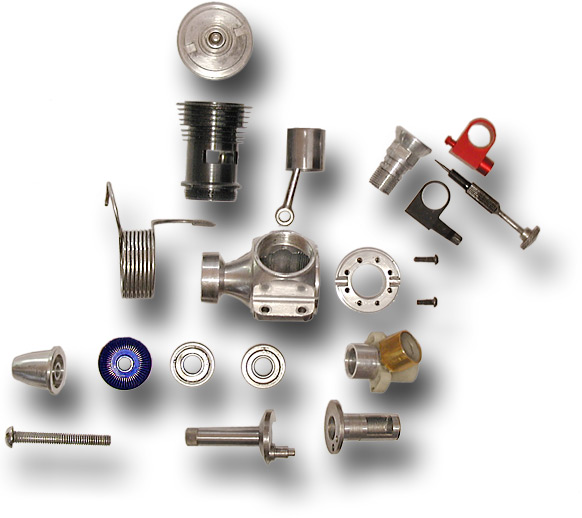

The cylinder is identical to the standard Olympic: dual ported with two distinctive, Tee-Dee-style boost channels along the edges. Sub-induction at top dead center is used.

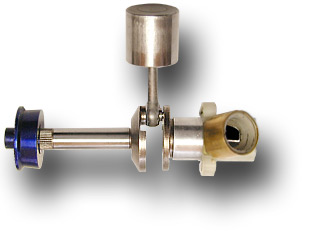

This picture shows the crankshaft and the rotary valve assembly which runs in an aluminum bearing embedded into a molded plastic housing. The crankshaft is supported by two identical, ball bearings of German origin (GMN R4)

Exploded view of the prototype engine of type B

The array of holes in the backplate and the elongated holes in the plastic part make it possible to adjust the timing over a wide range. Also the inlet can be oriented in any direction. The flange of the rotary shaft has two holes for coupling with the crankshaft pin.